Detailed e-Coating (electrophoretic-Coating) Process for Heat Exchangers and Radiators

Outokumpu, the world's largest supplier of copper and brass, reported in its "CuproBraze Technical Manual" the following: "Electrophoretic Coating [e-Coating] is the best technical solution to increase corrosion resistance [for heat exchangers]." (Section 7.2.3 Coatings)

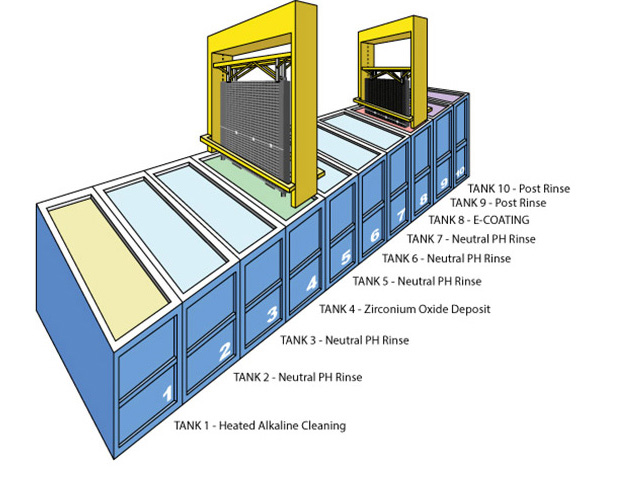

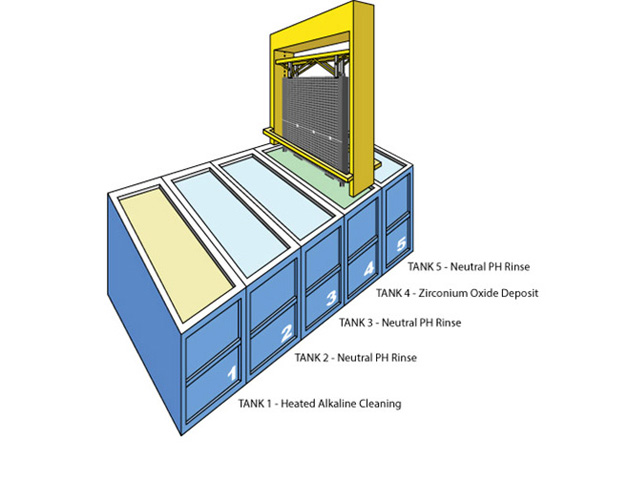

TANK 1 - The CoreKote Process starts with the removal of a weak Oxide layer that has formed in the bare surface. Heated Alkaline cleaning is used to remove the oxide film and any process lubricant residues

TANK 2 & 3 - A neutral PH rinse is used to remove the oxide film and process lubricant residues

TANK 4 - A full immersion process then deposits the Zirconium * Oxide layer on the surface of the material. A conversion layer forms on the surface enhancing improved fin edge build and adhesion.

* Zirconium corrosion resistance has been tested as a stand alone material, showing improved protection

- Organic Zirconium Pretreatment Designed For High Performance On All Substrates.

- Extremely Uniform Coatings Promote Uniform E-coat Applications

- Technology Proven In HVAC, Appliance, Construction, And Agriculture Industries.

- Zirconium Oxide Material is a High Strength Particulate Matter

- Formation of a Barrier Layer - Restricting Ion, Water and Oxygen Access to the Substrate

- Chemical and Mechanical Stabilization of the Native Oxide Film

- Environmentally Friendly, No Heavy Metals, Ambient Application

TANK 5 - Rinse

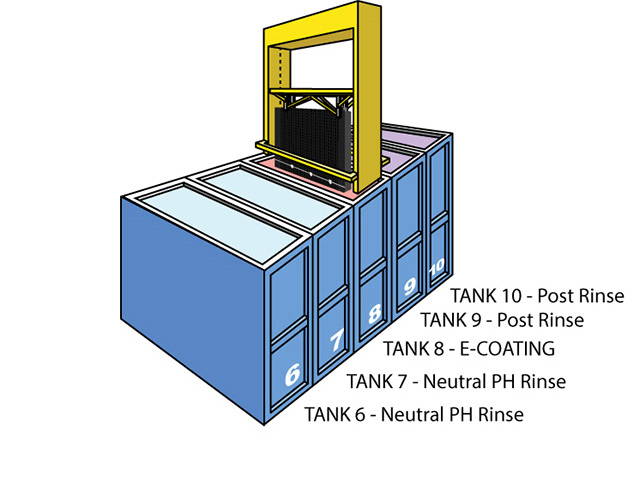

TANK 6 & 7 - After pretreatment, coils pass thru multiple rinse tanks to ensure a neutral ph surface.

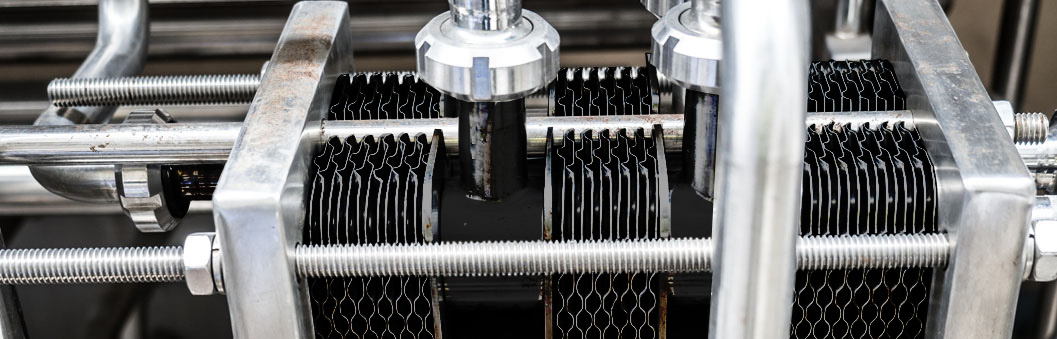

TANK 8 - E-COATING Full Immersion With our patented technology, film build is controlled to +- .0002. Anode control ensures no bridging and 100% coated to the center.

TANK 9 & 10 - Post rinse before curing ensures no loose material is left on the surface, contributing to an even film build.

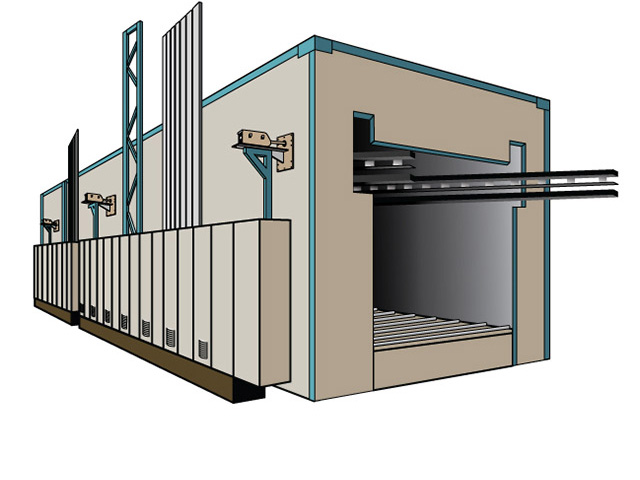

OVEN CURE - The next stage is oven cure. Axalta E-coat material is a lower temperature cure (355F) then other E-coats on the market.

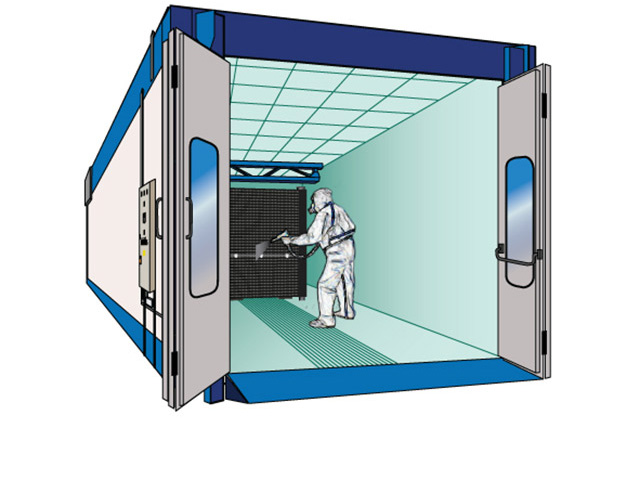

TOP COAT - Final stage is the Spray Top Coat. This provides an additional protective layer and attractive finish.